Next: Future Work Up: Image-Based Cloth Capture Previous: Feature Detection

[ pdf | chapters | single document ]

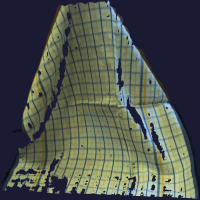

In order to evaluate the quality of the measurements, two meshes were constructed. The first mesh was built using the data acquired during the acquisition stage, using a heightfield to represent the acquired depth map, and applying the colour image as a texture on this heightfield. Since the source depth map is large (1024x768), this mesh has a lot of fine detail.

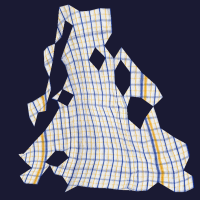

The second mesh was built using the detected grid vertices. A depth value was determined for each grid vertex by doing a lookup in the depth map. For a texture, a scan of the flattened cloth was used. The grid has only a small number of vertices (21x25), so this mesh is quite coarse.

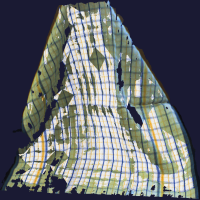

These two meshes are shown in Figure 7, along with a superimposition of the two. The colours in the two meshes are different, since the first mesh was acquired using a careful lighting setup to allow good depth measurement, while the second mesh's texture is simply a scan of the cloth. As can be seen in the superimposition, the grid lines match up quite well between the two meshes, indicating a good measurement of the grid vertex positions.

While capture was successful over the large, mostly flat regions of the cloth, there were problems in the large fold in the top left corner. Here, only sparse data was able to be captured. There are also patches of cloth that are missing, some of which were due to creases that were mistaken for grid intersections.

|

|

|